Khan, Ahsan Ali and Saad, Affendi and Mohd Isa, Mohd Zulfadli Isma

(2011)

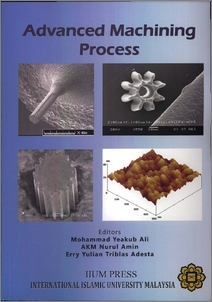

Wear ratio and work surface finish during electrical discharge machining (EDM) with eccentric electrode.

In:

Advanced Machining Processes.

International Islamic University Malaysia, Kuala Lumpur, Malaysia, pp. 7-11.

ISBN 9789674181628

![[img]](http://irep.iium.edu.my/style/images/fileicons/application_pdf.png)  Preview |

|

PDF ( Wear Ratio and Work Surface Finish during Electrical Discharge Machining (EDM) with Eccentric Electrode)

- Published Version

Download (537kB)

| Preview

|

Abstract

Abstract. In the present work the performance of eccentric electrode during EDM has been studied. Material removal rate and tool wear rate increase with increase in spindle speed and feed rate. It was found that higher feed rate increases the wear ratio. Spindle speed values determined the flushing efficiency. A higher spindle speed improves the flushing efficiency and thus improves the surface roughness.

Actions (login required)

|

View Item |

Download Statistics

Download Statistics Download Statistics

Download Statistics